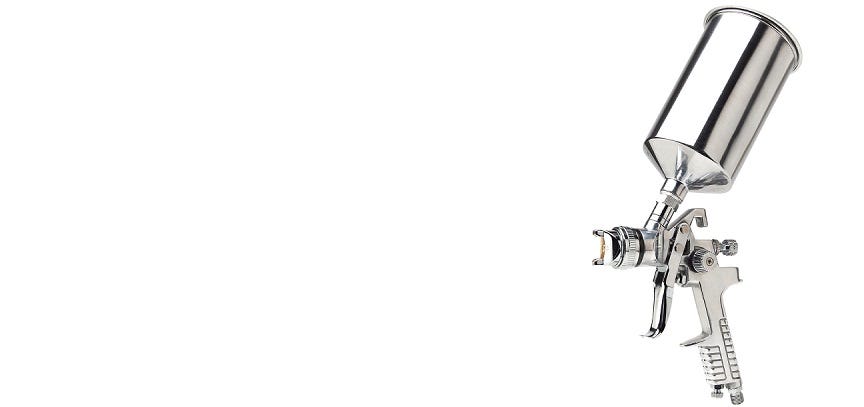

Hvlp Vs Lvlp Spray Gun

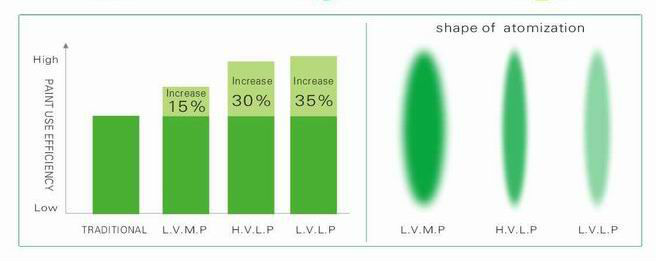

Hvlp vs lvlp spray gun. On the other hand LVLP stands for Low Volume Low Pressure. HVLP uses much higher-pressure air than LVLP. Conventional spray guns use high pressure to produce a relatively low volume of paint with the PSI the same at the inlet and the outlet.

I also prefer this system for my smaller projects boxes and small frames etc etc. The complaint air spray may or may not be accepted. The higher the pressure the.

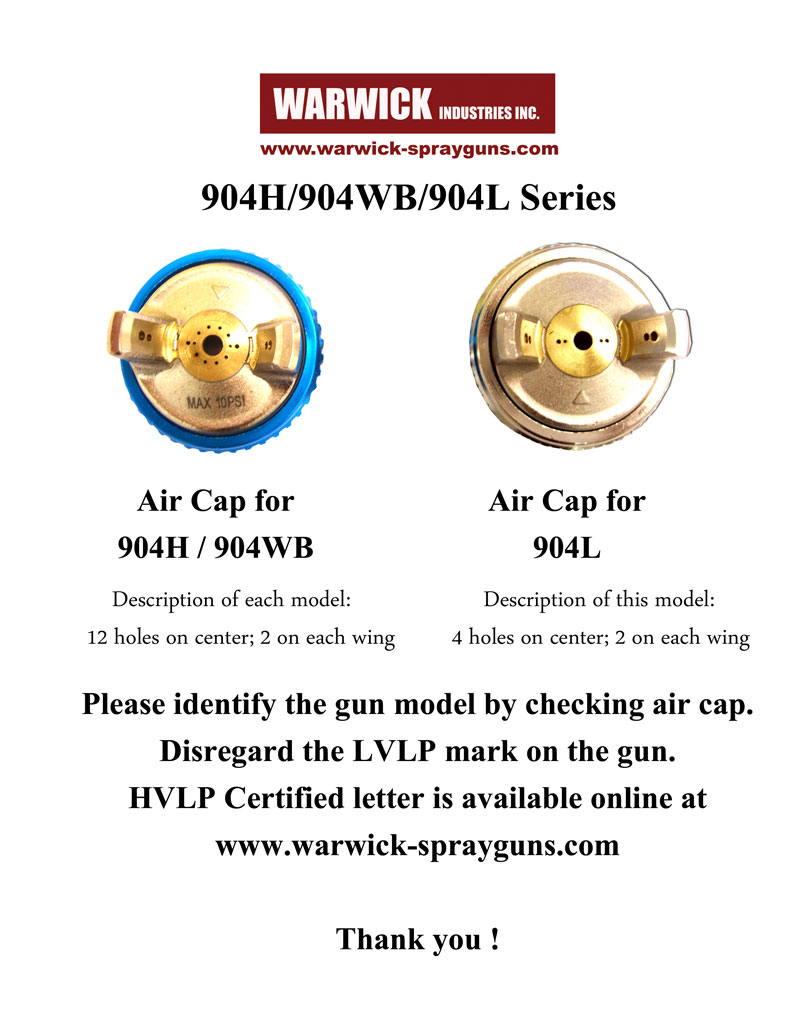

As such its not quite as efficient but its better with thicker materials. The end result is that transfer efficiency is similar to HVLP air guns around 60. The biggest difference between HVLP spray guns and LVLP spray guns is that LVLP spray guns need a lower amount of PSI in order to work perfectly somewhere near 10 PSI you can use almost any air compressor and the LVLP spray gun will still work perfectly.

These spray guns will deliver superb material transfer efficiency and hence minimizing waste. They both can be used for automotive and woodwork refinishing. What is a Non Bleeder Spray Gun A non-bleeder spray gun will have the option to use just air or air and fluid together to achieve a spray pattern.

Well to answer your original questionThe LVLP guns use less air pressure to atomize and therefore should allow less overspray if you know how to spray than HVLP guns and also will have less CFM needs. LVLP guns are the newest technology of the bunch I know there are exceptions. Compliant guns with their higher atomizing air pressure at the air cap will always atomize a coating finer than HVLP.

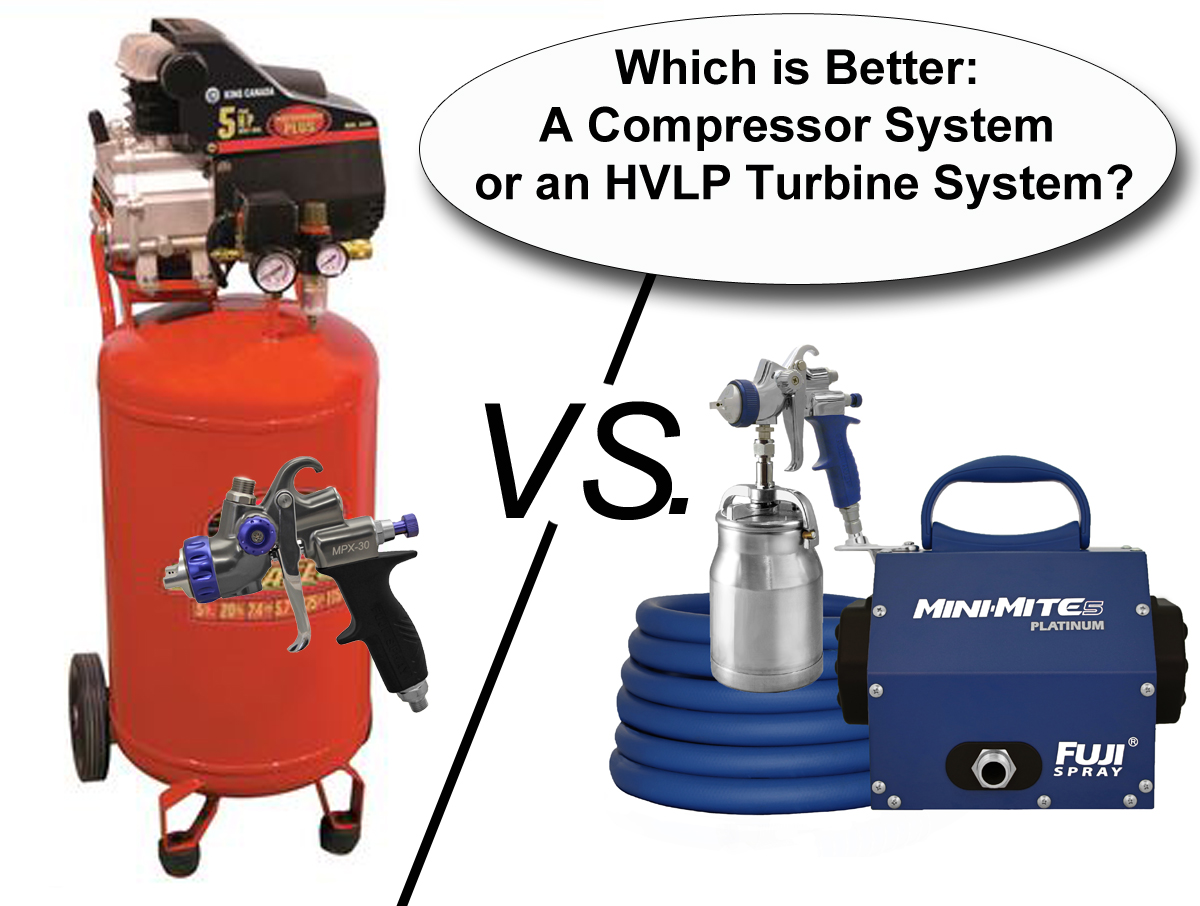

As an example compliant air spray will atomize water-based and industrial coatings easier than HVLP. The single biggest difference between an LVLP spray gun and an HVLP spray gun is that the HVLP spray gun will require a larger air compressor to operate at a higher volume without losing spray efficiency. There isnt as much over spray from the LVLP but Id still spray in a well ventilated area and.

I quickly cover the uses of HVLP and LVLP spray guns in this video. However all automotive basecoats and clear coat systems -- whether.

The Comparison Of HVLP Vs LVLP Spray Gun HVLP is the abbreviation of High Volume Low Pressure The name indicates this model can generate a high volume output with very low pressure.

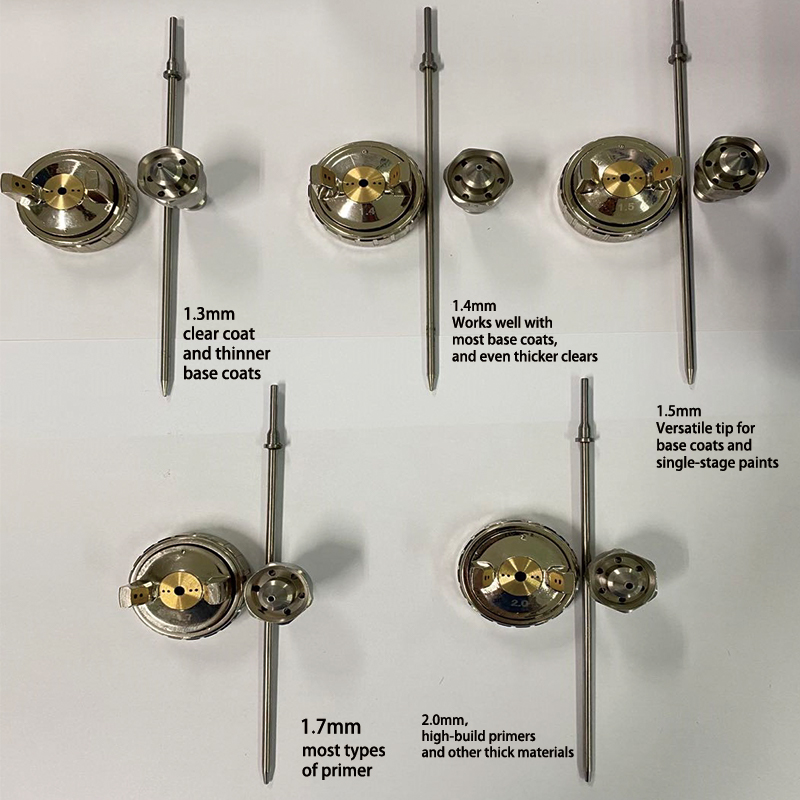

The biggest difference between HVLP spray guns and LVLP spray guns is that LVLP spray guns need a lower amount of PSI in order to work perfectly somewhere near 10 PSI you can use almost any air compressor and the LVLP spray gun will still work perfectly. The Comparison Of HVLP Vs LVLP Spray Gun HVLP is the abbreviation of High Volume Low Pressure The name indicates this model can generate a high volume output with very low pressure. LVLP spray guns and can proceed to the one that suits to your requirement. HVLP uses much higher-pressure air than LVLP. What is a Non Bleeder Spray Gun A non-bleeder spray gun will have the option to use just air or air and fluid together to achieve a spray pattern. On top of that LVLP spray guns have a tendency to spray slightly more slowly than a lot of HVLP spray guns. They use low pressures to propel paint about 10 PSI at the outlet. High Volume Low Pressure paint spray guns and Low Volume Low Pressure paint spray guns help you get the job done faster and easier. The LVLP system has a smaller fan and releases less finish so I dont have to move as fast as the HVLP so I can spray both sides on the front face of a round spindle on a stair case or childs cot.

On top of that it is recognized by EPA meaning its. Conventional spray guns are inefficient have a bad transfer rate only 35 waste a lot of paint material and create a lot of overspray. You can enjoy working with LVLP if you maintain well. The higher the pressure the. It ultimately depends on your choice and preference whichever paint gun you choose. In essence it uses less air than an HVLP air cap but with a slight bit more pressure than HVLP. As an example compliant air spray will atomize water-based and industrial coatings easier than HVLP.

Post a Comment for "Hvlp Vs Lvlp Spray Gun"